HygiTec – Thawing : Innovative thawing of frozen food

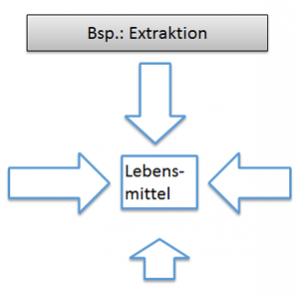

Water is a good solvent It also influences – Depending on the water hardness the osmotic pressure . With intensive contact with the food – soluble substances are dissolved or extracted . Thus, the food loses Colorants flavors but also weight (mass).

Novel antimicrobial based aerosol technology (Bio – Control), for an accelerated and hygienically safe thawing of frozen food (fish / meat …)

- Accelerated thawing by improved heat – mass transfer

- Decreased water losses

- No drying of fish or meat products

- Reduced energy demand

- Simple computer-controlled technology , easily integrated in operation

- Improved product quality , higher yields

- Optimized process and product hygiene : Improved seed status compared

- Improved functionality of the thawed products during further processing

With the HygiTec – thawing begins a new era for the thawing of frozen foods

Advantages over conventional methods: Energetic, temporally, qualitatively high hygienic microbial safety of process and product

- Novel Computerized thaw process

- Better moisture distribution / control through ultrasonic generated aerosols

- Maintaining the AW value during thawing

- Control of the set product parameters under hygienic conditions

- The thermal conductivity is enhanced by the 3-5μ large aerosol droplets by a multiple

- Energy and thawing times are reduced by about 30-40 %

- The quality characteristics of the treated by HygiTec products are in appearance, taste in natural color exceptionally well

- Very high hygienic – microbial product and process quality and safety

- The in conventionally Thawed products occurring mass loss and drying out of the surface , we greatly reduced

Prior thaw technology

For the Industrial thawing different applications are used :

- Frozen goods is thawed in thawing at room temperature uncontrolled and time intensive

- Thawingrooms or tunnels , heat by moving air, moisture is supplied by steam. High energy costs and relatively long thawing time

- Spraying tap water or heated water through irrigation . High water consumption and different depending on the season thawing

- Heat generation by high-frequency equipment ( microwave ) are expensive high investment costs and non-uniform heating is possible

- Thawing in moving water or water baths ( especially for fish ) have a high water consumption and strong nucleation possible

- As well as div. other methods

In the above process some drawbacks are to be expected:

- Mass loss, partially up to 10% – less flavor and color loss

- Structure and texture are adversely affected by the weakening of the cell walls not only the appearance is negatively affected , and flavors , minerals and vitamins are lost , thus it comes to be like straw and the taste is less intense

- In the further processing step on negative reactions , such as the adhesion is lost in the breading

Problems freezing and thawing: properties of ice

The freezing process including conventional thawing leads to changes in food examples:

Cell matrix changes by freezing and thawing

Precipitating proteins

- Mechanisms of protein precipitation – by slow freezing at low temperatures can lead to precipitation of proteins. Once the hydrogen bonds are disrupted by the withdrawal of the solution water. In addition, the acute water ice , which destroy the spatial structure of the protein molecules mechanically. Proteins gone lost by increasing the temperature also. Here areas of the protein molecule to be offset by the thermal motion to vibrate. Upon cooling, the original structure can not regress again.

Increased oxidative degradation of lipids

- Under lipid peroxidation refers to oxidative degradation of lipids. In this process take reactive radicals , electrons of lipids in the cell membrane and thus set a chain reaction that leads to cell damage Lipid peroxidation is also responsible for the destruction of animal and vegetable oils and fats.

Dehydration and loss of taste

- So may, for example by the action of cold freezer burn a food – the food is characterized dry. As a result, the pH decreases, the muscle proteins contract ( rigor mortis ) and lose their ability to retain water – the meat is dry and tough.

Shape and structure of the cell is destroyed

- When thawing in a water bath the fish continuously rinsed with water . The fish can withstand contact with water but not too good . It destroys the cell structures and allows the fish to get soft, pale and bland.

Significant limitation of water retention

- As the balance of the osmotic concentration gradient runs , depends mainly on the rate of thawing.

- Increased microbial contamination

- Adverse sensory quality characteristics